About Us

We are Manufacturer, Supplier, Exporter, Services Provider of Aluminum Blocks, Pump Body, Aluminum Pivot, Aluminum Motor Body, Precision Parts / Components, Casting Machine Parts / Components, Casting Parts / Components, Casting Pulleys, CI (Cast Iron) Pulleys, CI (Cast Iron) Casting Pulleys from Satara, Maharashtra, India.

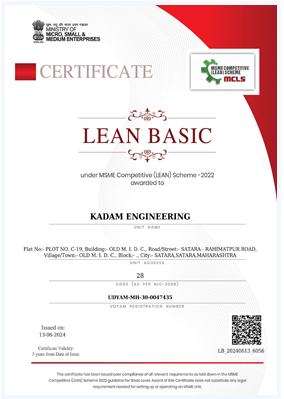

Mr. Pruthviraj Avinash Kadam began his engineering career in the manufacturing industry in 2018. After gaining expertise in foundry and machining, he decided to start their own business. Pruthviraj Avinash Kadam, a young entrepreneur, founded Kadam Engineering in 2022. Mr. Pruthviraj Avinash Kadam now handles all marketing, commercial, development, production, and quality department activities, with his younger brother, Mr. Ruturaj Avinash Kadam, in charge of production , Quality and HR. Furthermore, each department has a dedicated staff. Since 2022,This two youngster’s and his expertise Kadam Engineering team has been manufacturing machined metal components, automotive components, agricultural parts, non-automotive components, rail parts, CI casting parts, SCI casting parts, hub castings, pulley castings, CI casting machinery parts, cast iron parts, aluminum castings (HPDC, GDC) and parts.

To maintain the goodwill established, consumers refer to Kadam Engineering as an "Excellence in Casting and Machining Technology." Kadam Engineering has consistently produced high-quality work since its inception. Initially, Kadam Engineering manufactures all types of metal-machined components.

-

Management DetailsCompany Area

Land : 8000 Sq.ft. In OLD MIDC, Satara.

Construction : 6800 Sq.ft. Built up Shed.

MESDCL Electricity : 67 HP MECB Light Connection.

Solar Electricity : 48 KW Solar Power .

-

Manpower

5 Staff Member (Supervisor & Account Person)

16 Skilled Operator, 10 Semi skilled Operator

4 Helper, 2 Security Guard.

-

Future Plans

We expecting expansion of CNC , VMC & allied non conventional setup with highly precision and improved technology.

Additional plan for Painting booth/ Chamber facility at our end.

Additional plan for Horizontal Drilling machine & Milling machine.

Additional Plan for VTL machine.

-

Quality System & Manf. instructions

Visual & Gauge Inspection

Final inspection Plan for 100% Inspection

Control Plan for Production instructions

In-process Reports ( 1st Piece & Last Piece )

Quality Alerts

SOP